AL JAZEERA FACTORY

What is AAC?

AAC stands for Autoclaved Aerated Concrete blocks. It is a light- weight and highly thermal insulating concrete-based material used for both interior and exterior walls. It was developed in the 1930’s in Germany and became one of the most used building materials in Europe. AAC is now gradually being used all over the world by meeting sustainability and environment requirements, thus making it a Green Building Product.

Today with mass production of millions of cubic meter annually. There are hundreds of manufacturers all over the world. Almost all the international standard institutions like BS EN, ASTM, AS, DMS, etc. have this material specification included in their standards. Apart from using in Eastern and Western European countries and Turkey, AAC became much popular gradually all over the world. Now AAC is one of the most ideal and environment friendly building materials.

Today with mass production of millions of cubic meter annually. There are hundreds of manufacturers all over the world. Almost all the international standard institutions like BS EN, ASTM, AS, DMS, etc. have this material specification included in their standards. Apart from using in Eastern and Western European countries and Turkey, AAC became much popular gradually all over the world. Now AAC is one of the most ideal and environment friendly building materials.

Advantages of Using AAC

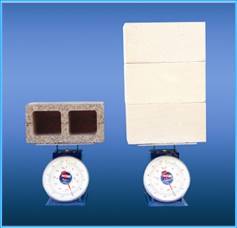

Reduces the loads up to 33%, on the concrete structure and foundation of the building.

A 10 cm thick AAC Thermalite block provides a 4hrs fire resistance and 15cm block provides 6hrs in accordance with BS-5628-3. This is approximately twice more than the normal concrete. J-Thermalite have been certified by UAE Ministry of Interior, Directorate of Civil Defense.

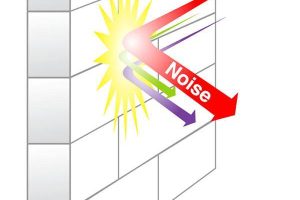

The cellular structure of AAC Blocks provides superior sound absorption and insulation, depending on density and porosity.

AAC block is 25% more stronger than other products of the same density.

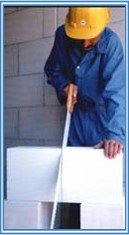

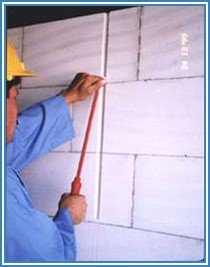

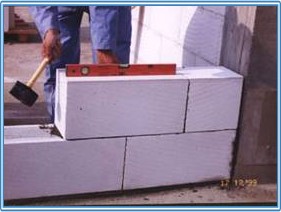

It can be sawed, nailed and drilled easier than wood, by suitable tools available for this purpose. It results in less wastes and keep the site clean.

J-Thermalite blocks are large in dimension and lighter than conventional blocks. It can be installed faster which is why construction time is substantially reduced.

Since 1930, the material has proved its durability under extremely different climate and chemical conditions.

No toxic substances, less consumption of fuel, electricity and nominal wastes during production, large saving of electricity – all these advantages of Thermalite reduces the environment pollution.

Because of cellular and discontinuous microstructure, AAC Thermalite walls provides superior resistance to air and moisture penetration than the traditional masonry products.

AAC Blocks Applications

Walls Applications

External & internal Walls

Partition wall

Load Bearing Wall

Party Wall

Smooth Face Wall

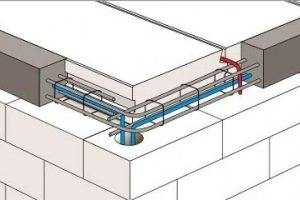

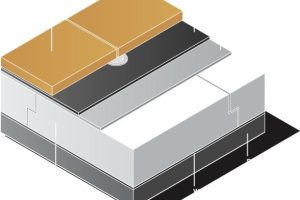

Roof Thermal Insulating system

Ceiling and Roof Applications

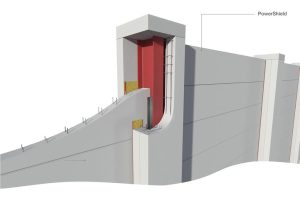

Fire Protection of steel

column and beam

Hourdi Blocks &

Lightweight Filler

Lintels & U block